NDT SOLUTIONS

Metallurgy NDT, LLC provides the following services and solutions:

Conventional PAUT

Phased Array Ultrasonic Testing (PAUT) utilizes a specialized ultrasonic transducer containing many individual elements that can be pulsed separately in a programmed pattern.

Applications:

- Weld quality inspection.

- Flaw characterization and critical sizing.

- In-service inspection, environmental crack detection.

- HTHA detection.

- Encoded nozzle weld inspection.

- Localized Corrosion Mapping.

- PSA vessel crack detection.

MUT Shear Wave

Shear wave testing, also known as angle beam inspection, is an ultrasonic testing technique used primarily for weld inspections.

A probe consisting of an ultrasonic transducer coupled with a plastic or epoxy wedge introduces an ultrasonic beam at an angle into a test area.

Applications:

- ASME and AWS weld quality inspection.

- Flaw characterization and critical sizing.

- In-service inspection, environmental crack detection and sizing.

AUT Corrosion Mapping

Automated Ultrasonic Testing (AUT) Corrosion Mapping maps the interior surface of pressure vessels, piping, heat exchangers, and more. It is often used for remaining life determinations as prescribed by the facility’s Mechanical Integrity program.

Applications:

- Corrosion monitoring and detection on vessel and piping.

Conventional TOFD

Although time-of-flight diffraction (TOFD) can be used for a variety of applications, its primary use is rapid weld testing of circumferential and axial weld seams, also known as perpendicular TOFD scanning

Applications:

- Weld quality in leu of radiography testing (RT) inspection.

- In-service inspection, environmental cracking detection.

- Defect critical sizing and monitoring.

- HDPE fusion weld inspection.

- Preferential corrosion detection and sizing.

COMPLEX GEOMETRY INSPECTION SOLUTION

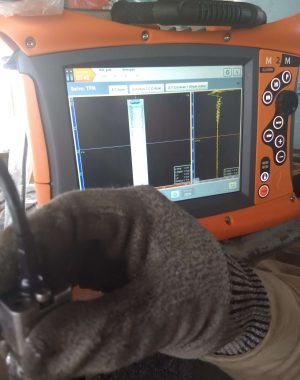

Ultrasonic Multi-Skip PAUT and Short Range Guided Wave (SRUT-GW) inspection for critical zones. Powerful Phased Array Pulser-Receiver electronics allow the full aperture emitting and receiving of ultrasonic signals. PAUT Scope instruments may be used for SRUT inspection and corrosion screening.

Applications:

- Not limited to: corrosion screening on annular ring of above ground storage tanks, corrosion under pipe support (CUP or TPC), raised face flange inspection (RFF), bolts inspection, above pipe supports and in interface areas (Air-soil, Vapor-Product).

Liquid Penetrant Testing

Examination using liquid penetrants (PT) allows discontinuities which are present at the surface of the part under examination to be detected.

Applications:

- Identification of fatigue cracks, pores, pin holes, overload and impact fractures.

HIGH TEMPERATURE HYDROGEN ATTACK (HTHA) DETECTION

Test screening performed using Time Of Flight Diffraction (TOFD). HTHA damage indications are confirmed using Phased Array Ultrasonic Testing (PAUT), Total Focusing Method (TFM) and Advanced Ultrasonic Backscatter Technique (AUBT).

DIMENSIONING

Assesses and confirms compliance with design specifications of machined parts and products through the measurement of geometric characteristics. Dimensional inspection services ensure the accuracy of the product features that can affect reliability and functionality.

Applications:

- Dimensioning inspection is often a critical step during product development or when determining fitness of a part that needs to be reused.

Magnetic Particle Testing

Magnetic particle testing (MPT) is used to detect surface and shallow subsurface discontinuities through magnetic flux.

Applications:

- Testing welds and other components for quality control, surface integrity and code compliance.

Total Focusing Method (TFM)

The Total Focusing Method (TFM) is an ultrasonic array post-processing technique which is used to synthetically focus at every point of a region of interest.

Applications:

- HTHA detection, detection and confirmation. – Environmental cracking detection, characterization. – Defect critical sizing. – Bolt inspection.

Hardness Testing (HT).

HARDNESS TESTING (HT).

Material Hardness Testing determines a material’s strength by measuring its resistance to penetration. Hardness test results can be extremely useful when selecting materials, because the reported hardness value indicates how easily the material can be machined and how well it will wear. Hardness testing is a critical NDE tool utilized to ensure that the welding, heat treatment and fabrication methods have not altered the original material of construction in a deleterious way.

Applications:

- Evaluation of a materials strength and wear resistance.

FIELD METALLURGICAL REPLICATION

Field Metallurgical Replication (FMR) is an NDT metallurgical inspection technique that is used for evaluating plant equipment such as heaters, boilers, piping and reactors. FMR is a simple process using portable equipment in which the metal surface is ground and polished to a mirror finish. The polished surface is subsequently etched to reveal the microstructure. A replica of the etched surface is then made with a thin piece of acetate film and the replica can is examined either in the field using a portable optical microscope or in a laboratory. This process gives our metallurgical engineers the ability to examine micro-structural features such as grain size, cracks, carbides, creep and other damage mechanisms.

Applications:

- FMR can confirm observations made by other non-destructive methods such as acoustic emission tests, penetrant examination and ultrasonic flaw detection to further identify the nature of the flaw.